Abstract: To investigate the weathering resistance of outdoor textiles, comparative tests were conducted on seven types of umbrella fabrics using laboratory-accelerated aging tests (employing the QUV accelerated weathering tester) and outdoor exposure tests (carried out in Dunhuang, Gansu; Wanning, Hainan; and Hangzhou, Zhejiang). The results indicate that for color changes, significant alterations were observed in both laboratory and outdoor tests, with a strong correlation between the two. Regarding strength degradation, substantial reductions were noted in both testing methods, making it challenging to compare their correlations directly. Nevertheless, this approach may serve as an effective product development test.

1. Introduction

Textiles encompass a wide range of products, including not only common items like clothing and fabrics but also outdoor textiles such as tents, rain tarps, sunshades, outdoor apparel, industrial fabrics, and covers. For outdoor textiles, factors such as light, water, and high temperatures can all induce degradation. Therefore, accelerated aging test conditions must be designed to simulate outdoor application environments. Outdoor textile materials include not only plant fibers but also polyester and coatings. To investigate the weathering resistance of outdoor textiles, UV accelerated aging tests and outdoor exposure tests were conducted on seven types of umbrella fabrics in Dunhuang (Gansu), Wanning (Hainan), and Hangzhou (Zhejiang).

The UV ultraviolet (UV) accelerated weathering tester is a simple, reliable, and user-friendly device. Tens of thousands of UV testers are used worldwide, making it the most widely adopted UV aging equipment. The QUV tester employs specialized fluorescent UV lamps to simulate sunlight and uses condensation humidity and water spray to replicate dew and rain, authentically reproducing material damage caused by sunlight. Typical damage modes include fading, loss of gloss, chalking, cracking, blistering, embrittlement, strength reduction, and oxidation.

2. Experiment

2.1 Principles of Weathering Aging

Weathering aging is primarily caused by three factors: light, temperature, and humidity. Any single factor can induce material degradation, and their combined effects exceed the damage caused by any individual factor alone.

2.1.1 Light

The chemical bonds in polymer materials exhibit varying sensitivity to different wavelengths of sunlight, each with a specific threshold. Short-wave UV radiation in sunlight is the main contributor to the physical aging of most polymers, such as the C-N bond threshold at 393 nm. However, long-wave UV radiation and even visible light can degrade certain dyes and pigments, causing discoloration and fading.

2.1.2 Temperature

Higher temperatures accelerate chemical reaction rates. Although temperature does not affect the photochemical reaction rate in light-induced degradation, it influences subsequent reaction kinetics. Consequently, temperature effects on material aging are often nonlinear.

2.1.3 Humidity

Water directly participates in material aging reactions. Relative humidity, dew, and rain are the primary forms of moisture in nature. Studies show that outdoor materials remain in a潮湿 state for 8–12 hours daily, with dew being the predominant cause. Dew inflicts greater damage than rain due to its prolonged adhesion to materials, leading to more severe moisture erosion.

2.2 Experimental Design

To compare the weathering resistance of outdoor textiles, seven umbrella fabrics were selected as test specimens. Laboratory-accelerated aging tests used the QUV UV tester, while outdoor exposure tests were conducted in Dunhuang, Wanning, and Hangzhou.

2.3 Test Specimens

A total of seven white umbrella fabrics were tested: polyester pongee, solid-color polyester-A, nylon, solid-color polyester-B, chameleon fabric, oxford fabric, and polyester plain weave. All specimens were provided by Hangzhou Paradise Umbrella Group Co., Ltd. Each specimen underwent four tests, six performance measurements, four destructive evaluation items, and five replicates per evaluation, totaling 480 replicates per sample.

2.4 Test Equipment

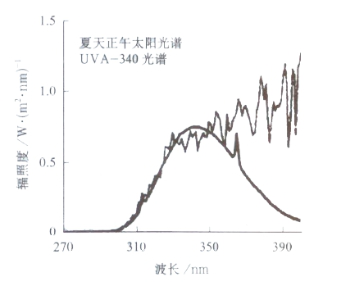

The QUV UV accelerated weathering tester utilizes fluorescent UV lamps to simulate solar radiation damage to durable materials. Different lamp types generate distinct spectra for varying application conditions. The UVA-340 lamp excels in simulating short-wave UV radiation, with its spectral power distribution (SPD) closely matching solar radiation from the cutoff wavelength to approximately 360 nm (Figure 1). The UVB-313 lamp accelerates aging via short-wave UV radiation, making it suitable for testing highly durable materials or quality control.

The UV tester simulates dew damage through condensation: heating a water pan at the tester’s base generates vapor, while the specimen surfaces, acting as the test chamber walls, are exposed to cooler ambient air. This temperature differential induces condensation, forming liquid water on the specimens. Additionally, water spray can simulate rain impacts, thermal shock, or mechanical erosion. Notably, only the UV tester incorporates condensation functionality, critical for replicating prolonged outdoor damp exposure (8–12 hours daily).

2.5 Test Conditions

2.5.1 Laboratory-Accelerated Aging

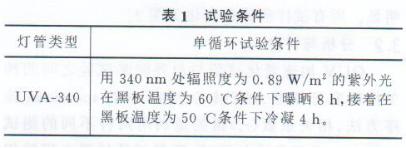

The QUV tester’s UV exposure and condensation cycles simulate short-wave UV radiation and dew damage, respectively, while water spray replicates rain effects. Test conditions followed GB/T 31899-2015 Textiles—Weathering Resistance Test—UV Exposure (Condition 1), with a total exposure duration of 300 hours (Table 1).

2.5.2 Outdoor Exposure

Outdoor tests were conducted at three sites: Dunhuang (arid desert climate), Wanning (subtropical climate), and Hangzhou (urban wetland climate). Specimens were continuously exposed southward at 45° for six months without back panels.

2.6 Testing Procedures

Color changes, tearing strength (warp/weft), and breaking strength (warp/weft) were measured. QUV tests evaluated specimens every 50 hours (300-hour total), while outdoor tests assessed specimens monthly (6-month total).

3. Results and Discussion

3.1 Color Changes

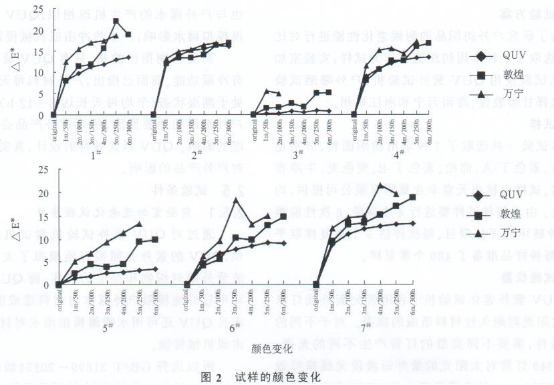

Color variations were quantified using the CIE Lab* color space (ASTM D2244) with D65 illuminant, 10° observer, and specular-included mode. Both QUV and outdoor tests induced significant color changes in most specimens (Figure 2).

3.2 Correlation Analysis

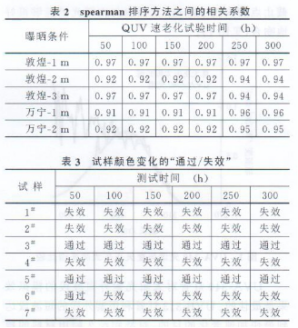

The Spearman rank correlation coefficient (rs) was calculated per ASTM G 169 to evaluate correlations between QUV and outdoor test results:

rs=1−N(N2−1)6∑Di2

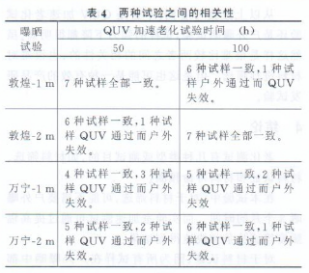

where N is the sample count and Di is the difference in ranks between paired tests. Specimens were ranked by ΔE* (color difference) values. Correlation coefficients (Table 2) and pass/fail criteria (ΔE* < 5.0 = pass; ΔE* > 5.0 = fail) (Tables 3–4) indicated strong agreement between QUV and outdoor tests. Future studies should include non-white specimens.

3.3 Strength Degradation

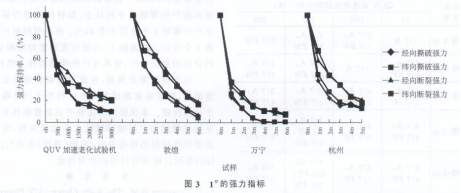

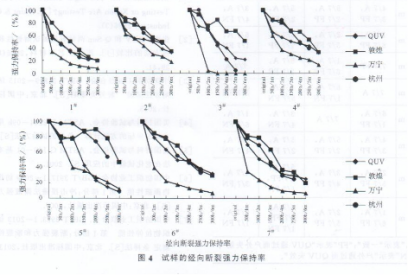

Tearing strength (GB/T 3917.1) and breaking strength (GB/T 3923.1) were measured for warp and weft directions. Most specimens exhibited significant strength losses in both tests, with minimal directional variation (Figure 3). Focus was placed on warp-direction breaking strength retention (Figure 4).

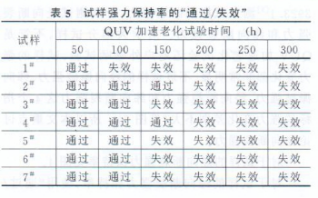

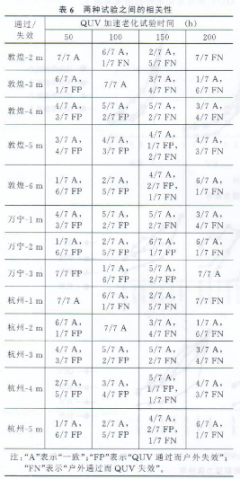

Using pass/fail criteria (retention > 50% = pass), correlations between UV and outdoor tests were analyzed (Tables 5–6).

Both tests showed substantial strength reductions, complicating material screening but aiding in product development.

4. Conclusion

Accelerated testing serves purposes like material screening, certification, and lifetime prediction. For screening, 3-month outdoor exposure may be redundant; laboratory tests can expedite results via elevated irradiance. For certification, rapid outdoor degradation necessitates developing materials with ≥80% strength retention after 3-month exposure, followed by accelerated testing to establish correlations. For lifetime prediction (acceleration factors), this study lacked sufficient data to correlate laboratory and outdoor results. However, pass/fail data already reflect material performance, reducing the necessity for explicit lifetime predictions.

在线客服

在线客服